Industrial AI agents are the new frontier in the manufacturing industry. Rising costs, labor shortages, trade wars, and other external factors are forcing manufacturers to take a balanced approach with their long-term strategies and near-term operational needs.

Supporting this shift to a new paradigm, industrial AI agents are enabling autonomous workflows with a tight-knit-knit fabric of OT and IT. As the new frontier technology, it’s pushing industrial innovation further with unprecedented use cases.

In this context, let’s explore 6 trends that will redefine the manufacturing industry.

6 manufacturing trends in 2026

Resilient supply chains

With the uncertainties around trade and tariffs, global supply chains will become more complex. To build resilience with such geopolitical and socioeconomic shocks, manufacturers should invest in building agentic AI solutions.

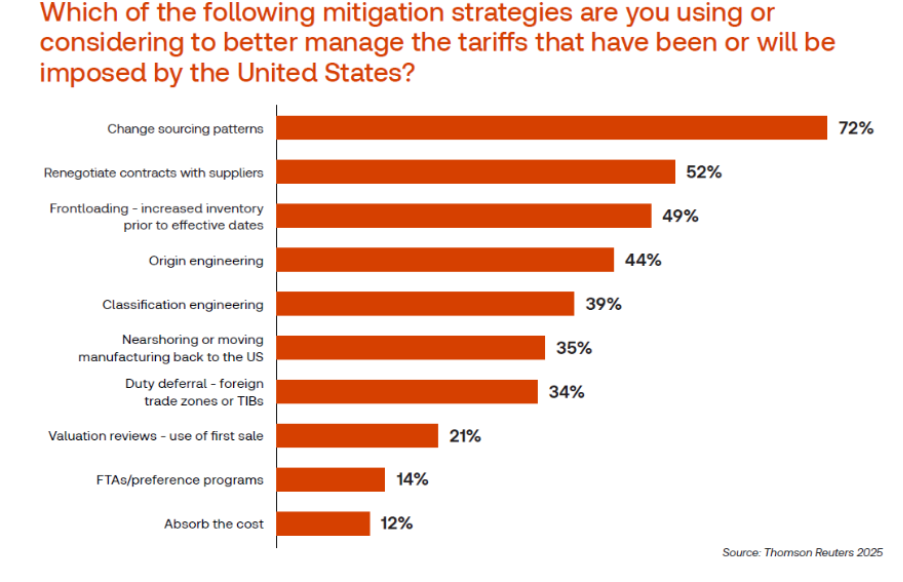

The Thomson Reuters 2025 Tariffs survey say that businesses are already including digital solutions in their risk mitigation strategies. AI agents will help you strengthen these strategies and stay resilient in 2026 and beyond.

AI agents can continuously monitor trusted sources to track disruption. For example, updated tariffs and trade policies, extreme weather, etc. Integration with your enterprise systems, like SCM, CRM, ERP, gives AI agents complete visibility into the supply chain.

Analyzing data from the internal and external systems, agents can predict the potential impact of the events and make recommendations to balance costs and risks.

Maximize value from ERP systems

A Deloitte analysis found that 69% of business leaders feel negative or neutral about their ERP investments. ERP systems hold powerful data that can support informed decision-making and drive growth.

However, complexities in integrating existing processes and adoption challenges are key roadblocks in maximizing business value.

AI agents can help you balance ERP costs and drive innovation. For example, an AI agent integrated with the SAP ECC system can unlock revenue growth opportunities.

This is exactly what an American sports equipment manufacturer did. They implemented an AI agent that delivers personalized recommendations and actionable insights for their field sales reps.

This timely assistance helps the reps unlock sales opportunities and strengthen customer relationships.

There are many other powerful use cases for AI agents that can maximize value from your ERP investments.

Bridging knowledge gaps

Manufacturing is currently experiencing a wave of retirement. Since it is a trade of skills, the upcoming young workforce requires a lot of training and quick assistance on the shop floor. With traditional knowledge management, it is challenging to access institutional knowledge scattered across files in the back-office systems.

You need a human-centric digital solution to plug this knowledge divide, and enterprise-grade AI agents will bridge the gap.

Multimodal agents can read, analyze, and summarize information from different sources. You can integrate these agents with your knowledge base and make it accessible for your tech via an intuitive chat or voice interface.

Techs can ask questions or upload media files, and the agent will get the right information from trusted sources to help them do their job efficiently. This quick access to knowledge will accelerate the repair turnaround time (RTAT) and workorder completion rates.

Occupational safety and health (OSH)

An energy company in India implemented an AI agent for monitoring their shop floor activities. The agent can detect employee movements around restricted areas and send alerts to security managers with evidence. They also implemented another agent that can monitor vehicle movement and detect violations.

These agents helped the energy company enhance their occupational safety and health (OSH) and enabled them to respond much faster to incidents. This scenario highlights the potential use cases for AI agents in OSH; and we will see a growing adoption.

Multimodal AI agents can mimic the human brain and significantly contribute to OSH in manufacturing. They can take up several key roles, including hazard detection, real-time monitoring, training and simulation, incident investigation and reporting, and health monitoring.

AI agents can be a great addition to occupational safety in critical environments where employees deal with hazardous materials or heavy machinery.

Pretrained AI agents can continuously monitor feed from IOT systems and perceive their environment. They can trigger alerts and promptly respond to incidents, just like a human would do. Deep integration with your digital ecosystem can make them more agile and efficient in mitigating risks.

Reducing downtime and enhancing OEE

Unplanned downtimes cost $125,000 per hour, a study by ABB found. Keeping the production lines running requires autonomous maintenance. Industry 4.0 introduced several OT and IT technologies empowering maintenance managers with near real-time data. AI agents will deepen the shift by minimizing human intervention in the maintenance process and cutting down the turnaround time.

They continuously monitor asset health and enable adaptive workorder planning. From detecting potential break down to creating work orders, automating approvals and assigning jobs to technicians, agents can autonomously perform critical maintenance tasks. As we discussed earlier, they bridge the knowledge divide and boost mean-time to repair.

Streamlined contract management lifecycle

Fortune 2000 companies have 20,000 to 40,000 active contracts at any given time. Managing this large volume of contracts with traditional practices drives up the costs and leaves gaps in the process. Contract management challenges are causing an 8.6% value erosion and impacting financial performance of businesses.

Contract managers are trapped in routine tasks. Drafting and approvals alone take away most of their time. Whereas you need their skills and time in negotiating, compliance monitoring, risk management, and other value-added activities.

AI agents bring several technical capabilities complementing your cognitive capabilities. This culmination will enable a more strategic, relational approach supported by large-scale analytics. This transformation will reposition contract managers as proactive, strategic business advisers with greater ownership.

Grab the competitive advantage with AI agents in Manufacturing

AI agents create an opportunity to leapfrog in the race to leading industrial transformation.

However, agentic AI initiatives need solid data foundation and governance guardrails to be successful. Integration with your existing workflows is an imperative to enable autonomous workflows.

At Digital ClerX, we are helping businesses grab the competitive advantage with AI agents. Have a specific manufacturing use case in mind? Let’s talk and bring your vision into reality.